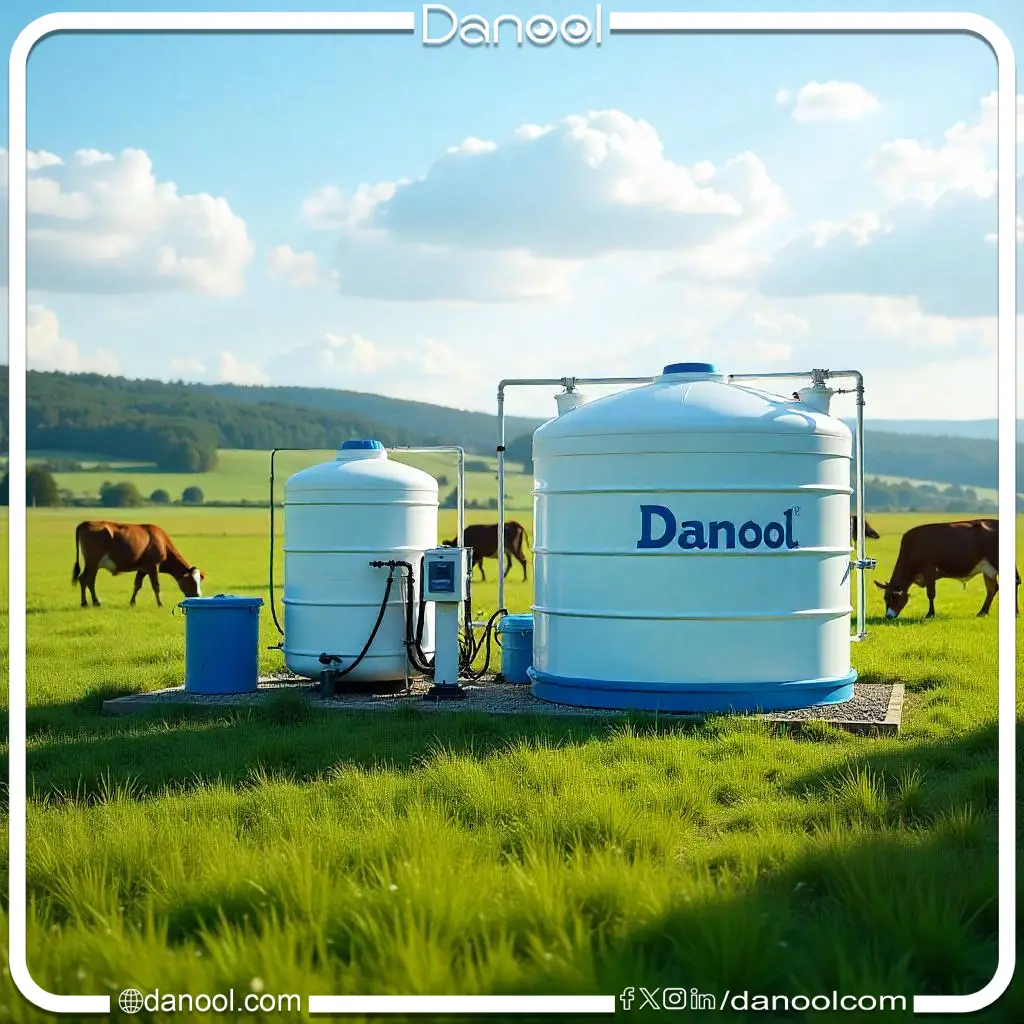

Small water desalination and purification plants have become a necessity in the modern age, especially in areas suffering from a shortage of fresh water sources. A water desalination and purification plant with a production capacity of 5000 liters per day is an ideal solution for limited uses such as large houses, small farms, or commercial establishments. In this article, we will discuss the details of the components of the desalination plant, its working mechanism, as well as the factors that determine its cost.

Components of a 5000-liter per day water desalination and purification plant.

The small water desalination and purification plant consists of several main components that work together to achieve the best water quality suitable for drinking or other uses.

1. Intake and Preliminary Treatment Unit:

- Suction Pump It works by drawing water from the source, whether it's a well, tank, or seawater.

- Sand Filter Removes large particles such as dust and sediments.

- Carbon filter: It removes organic materials and chlorine to improve water quality and protect the membranes.

- Micron filter: Removes small particles that may affect the efficiency of the membranes.

2. Reverse Osmosis System.

- High-Pressure Pump. Used to increase water pressure and enable it to pass through the reverse osmosis membrane.

- Semi-permeable membranes It is the main component that removes salts, heavy metals, and dissolved substances from the water.

- Salinity removal unit The salty water resulting from the purification process is discharged.

3. Final treatment unit.

- Acidity adjustment device It balances the acidity in the water to make it safe and suitable for drinking.

- Ultraviolet (UV) disinfection unit It is used to disinfect water and eliminate bacteria and viruses.

- Mineral addition It reintroduces essential minerals to improve the taste and quality of the water.

4. Produced water tank.

- A sealed storage tank made of rust and bacteria-resistant materials, designed to store purified water ready for use.

5. Control and monitoring panel.

- Digital display It displays operational data such as water pressure, salinity ratio (TDS), and flow rates.

- Sensors To monitor water quality and system efficiency.

6. Pipes and fittings.

- Pipes and fittings made of corrosion-resistant materials to withstand high pressure and ensure no water contamination during operation.

Mechanism of operation of the water desalination and purification plant.

A 5000-liter per day desalination plant works through integrated steps to convert raw water into pure water. These steps include:

- Water extraction from the source: Using a suction pump, the raw water is transferred to the plant.

- Primary treatment Large impurities such as sediments, chlorine, and organic materials are removed using different filters.

- Reverse osmosis desalination: The water is pressurized through reverse osmosis membranes that separate salts and contaminants from the water.

- Final treatment The water's pH is adjusted, essential minerals are added, and it is disinfected.

- Storage The purified water is stored in a sealed tank before being distributed for use.

Factors that affect the cost of a desalination plant

The cost of the station varies depending on the manufacturer and the availability of accompanying installation and maintenance services.

1. Type of raw water:

- The cost of the station varies depending on the type of water being treated; well water treatment differs from seawater treatment due to the salt concentration.

2. Component quality

- Prices vary depending on the quality of components used, such as membranes, pumps, and filters. High-quality components last longer and operate with higher efficiency.

3. 2. Plant design

- The design of the station and its technological advancement affect its cost. Stations that have smart control systems and advanced sensors are typically more expensive.

4. Storage tank capacity

- The capacity of the tank associated with the station affects the price. Larger tanks are more expensive.

5. Optional add-ons

- Such as ultraviolet (UV) disinfection units or mineral addition systems. These options add additional costs to the station.

6. Consumed energy

- Energy consumption efficiency is an important factor, as stations that consume less energy are considered more economical in the long term, even though they may have a higher initial cost.

7. Installation and maintenance services

- The cost of the station varies depending on the manufacturer and the availability of accompanying installation and maintenance services.

Uses of a desalination plant with a capacity of 5000 liters per day

Small desalination plants with a capacity of 5000 liters per day are used in various applications, including:

- Home use:

- To provide drinking and cooking water for a large family or a group of households.

- Commercial establishments:

- Like restaurants, cafes, and small hotels.

- Agricultural use:

- To provide low-salinity water for irrigating crops or for hydroponic farming.

- Small industrial facilities:

- For using water in cooling or production processes.

- Remote areas:

- To provide drinking water in areas suffering from a shortage of fresh water supplies.

Benefits of a water desalination and purification plant with a capacity of 5,000 liters per day.

- An economical and environmentally friendly solution:

- It provides a sustainable solution to meet daily water needs without relying on limited natural water resources.

- High efficiency in water purification:

- Capable of removing up to 99% of salts and contaminants.

- Compact and easy-to-transport design:

- It fits small spaces and can be used in temporary or remote locations.

- Operational flexibility:

- It can be operated using various energy sources, including electricity or solar power.

- Reducing reliance on bottled water

- It reduces the cost of purchasing bottled water and minimizes plastic waste.

Components of a 5000-liter per day water desalination and purification plant.

| Item | Description |

|---|---|

| Plant capacity | 5000 liters per day (5 m³). |

| Uses | Homes, commercial establishments, agriculture, small industries, remote areas. |

| Essential components | – |

| Suction Pump | It draws water from the source (well, reservoir, sea). |

| Sand filter | It removes sediments and large particles (sand, dust). |

| Activated carbon filter: | It removes chlorine and organic materials, improving water quality. |

| Microfiber filter | It removes fine particles that may damage the membranes. |

| High-pressure pump | It increases the water pressure to enable it to pass through the reverse osmosis membranes. |

| Reverse osmosis membranes | It removes salts, heavy metals, and dissolved substances up to 99%. |

| Saline water disposal unit | It eliminates the salty water produced by the desalination process. |

| Acidity adjustment device | It balances the water's pH to make it safe and suitable for drinking. |

| Ultraviolet (UV) disinfection device | It disinfects the water and kills bacteria and viruses. |

| Mineral addition unit | Essential minerals such as calcium are added to improve water quality. |

| Raw water tank: | The storage tank for the produced water is made of materials resistant to rust and bacteria. |

| Control and monitoring panel. | Operational data such as water pressure and salinity ratio (TDS) are displayed. |

| Operating mechanism | – |

| Suction | The raw water is extracted from the source using a suction pump. |

| Primary treatment | The water passes through filters to remove impurities, sediments, and chlorine. |

| Reverse osmosis desalination: | The water is pressurized through membranes that separate salts and harmful minerals. |

| treatment unit. | pH adjustment, addition of essential minerals, and disinfection of the water. |

| Storage | The purified water is stored in a sealed tank, ready for distribution. |

| Advantages | – |

| Small size | Suitable for small spaces, easy to transport and install. |

| High efficiency | It removes up to 99% of salts and impurities. |

| Cost-effective | Lower cost compared to large plants, with flexibility in maintenance. |

| Environmentally friendly | It reduces the cost of purchasing bottled water and minimizes plastic waste. |

| Moderate energy consumption | Efficiency in operating the plant to reduce energy costs. |

| Challenges | – |

| Disposal of saline water | It requires an appropriate drainage system to protect the environment. |

| Regular maintenance | It requires regular monitoring and maintenance to ensure operational efficiency. |

| Stability of the power source | It requires a stable power source to operate the pumps and the reverse osmosis system. |

A water desalination and purification plant with a capacity of 5,000 liters per day is an innovative and effective solution to provide fresh water for domestic, commercial, and industrial uses. Its compact design and high efficiency make it an ideal choice for small communities or facilities that require limited amounts of water. When choosing a desalination plant, it is important to consider the quality of components, the nature of the raw water, and maintenance requirements to ensure sustainable performance and achieve the highest value for the cost.